Pulverized coal large pipe chain conveyor

1、 Overview of Pipe Chain Conveyor

The pipe chain conveyor is a continuous conveying equipment for conveying loose materials such as powder, small particles, and small pieces, which can be combined horizontally, obliquely, and vertically for conveying. In a closed pipeline, the chain is used as the transmission component to drive the animal material along the pipeline. When transported horizontally, the material particles are pushed by the chain in the direction of movement. When the internal friction force between the material layers is greater than the external friction force between the material and the pipe wall, the material moves forward with the chain, forming a stable material flow; When vertically conveying, the material particles inside the pipe are pushed upwards by the chain, and the lower feeding prevents the upper material from sliding down, generating lateral pressure, thereby enhancing the internal friction force of the material. When the internal friction force between the materials is greater than the external friction force between the material and the inner wall of the pipe and the weight of the material, the material is transported upwards with the chain, forming a continuous material flow. Powder materials can move or change direction in a straight line along a closed pipeline in three-dimensional space; The horizontal conveying distance can reach 60 meters, and the vertical conveying distance can reach 30 meters.

In the process of conveying materials, the pipe chain conveyor has the characteristics of large conveying capacity, long service life, low maintenance cost, good sealing, safety, and low energy consumption of the buried scraper conveyor. It also has the vertical conveying ability of the bucket elevator, and the layout is more flexible (horizontal vertical/inclined horizontal), with higher sealing performance. The characteristics of no return material, no damage to materials, and no dust in vertical material transportation. When conveying materials with water content, easily adsorbed materials, and light specific gravity, an electric cleaner can be installed inside the chassis.

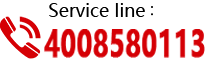

Layout form of pipe chain conveyor

1. Horizontal type 2. inclined type 3.vertical type 4.three-dimensional layout

2、 Performance characteristics of pipe chain conveyor:

1. Compact structure, occupying small space, able to change the conveying direction in three dimensions, unaffected by terrain, angle, and height; The conveying process is carried out in a closed pipeline without dust flying;

2. The conveying process is balanced, with minimal internal movement between materials and minimal damage, ensuring material quality and suitable for abrasive materials;

3. It will not cause system blockage and is suitable for conveying materials of various forms;

4. The transportation of mixed materials will not result in material layering;

5. Large conveying capacity, low energy consumption, greatly reducing equipment operating costs;

6. All moving parts operate in a closed space, safe and reliable;

7. Can achieve long-distance transportation;

8. Multiple inlet and outlet ports can be freely deployed to meet process requirements;

9. Easy to achieve centralized control and improve automation level.

3、 Application fields of pipe chain conveyors

1. Rubber and plastic industry: PP, PVC, PE and other powders, ABS, PC, PP, PE and other particles

2. Building materials: cement, clay, yellow sand, quartz sand, clay, silicon powder, calcium carbonate powder, dolomite powder, sawdust, glass fiber, silica, etc

3. Fine chemical industry: dyes, pigments, coatings, carbon black, titanium pigments, iron oxide, ceramic powder, heavy calcium carbonate, fine particle calcium carbonate, bentonite, activated carbon

4. Pesticides: urea, ammonium chloride, ammonium bicarbonate, soda powder, solid insecticides

5. Food industry: flour, starch, grains, milk powder, food additives, fish oil, etc

6. Metal and other powders: tungsten powder, copper ore powder, coal powder, block phosphate, bauxite, etc

4、 Technical parameters

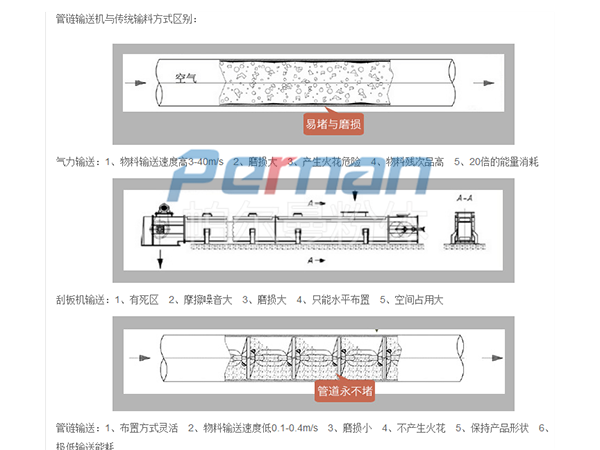

5、 What are the advantages of a pipe chain conveyor compared to other conveying equipment

1. Good sealing performance: The entire system operates in a closed pipeline, without leakage or dust. It can be filled with gas to protect the transported materials and avoid environmental dust pollution.

2. Energy saving: Point contact between the conveying chain plate and the conveying pipeline, low friction, and low power consumption.

3. Three dimensional conveying: combined conveying methods such as horizontal, inclined, vertical, and turning.

4. Volume conveying: The material will not be squeezed, ensuring the integrity of the material.

5. Simple structure: The driving and driven chassis have a simple structure, low failure rate, convenient operation, long service life, and low maintenance rate.

6、 The pipe chain conveyor can be used as a supporting equipment for ton bag unpacking machines and automatic unpacking machines, achieving dust-free unpacking and feeding.