Zinc oxide pipe chain conveyor site

Product Introduction

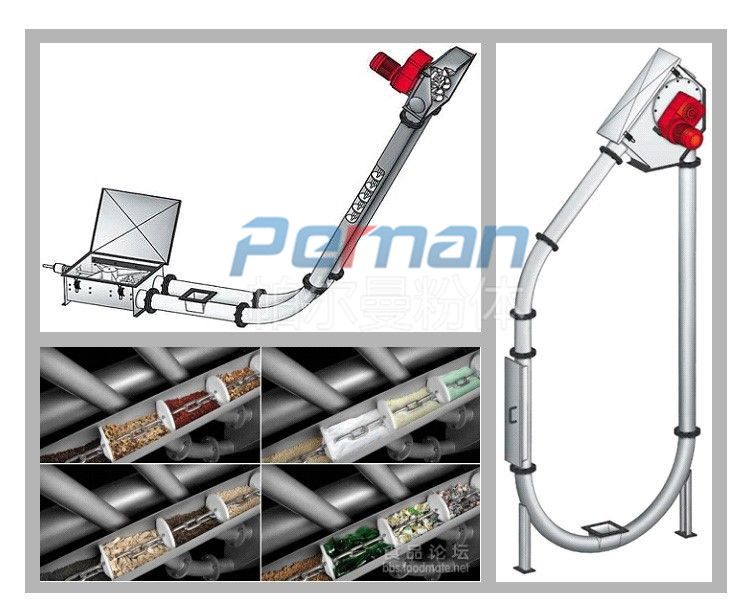

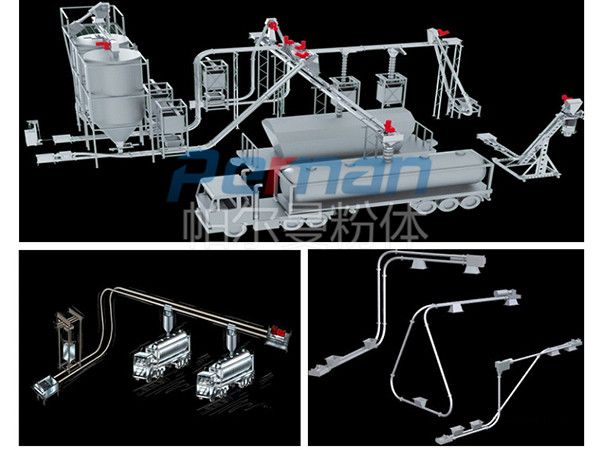

The pipe chain conveyor, also known as the chain plate conveyor, is a mechanical system that moves inside a closed pipe. It has the characteristics of stable performance and energy saving in the conveying system. It can continuously transport loose materials such as powder, small particles, and small pieces, and can also be combined horizontally, obliquely, and vertically.

In a closed pipeline, the chain is used as the transmission component to drive the animal material along the pipeline. When transported horizontally, the material particles are pushed by the chain in the direction of movement. When the internal friction force between the material layers is greater than the external friction force between the material and the pipe wall, the material moves forward with the chain, forming a stable material flow; When vertically conveying, the material particles inside the pipe are pushed upwards by the chain, and the lower feeding prevents the upper material from sliding down, generating lateral pressure, thereby enhancing the internal friction force of the material. When the internal friction force between the materials is greater than the external friction force between the material and the inner wall of the pipe and the weight of the material, the material is transported upwards with the chain, forming a continuous material flow. Powder materials can move or change direction in a straight line along a closed pipeline in three-dimensional space; The horizontal conveying distance can reach 60 meters, and the vertical conveying distance can reach 30 meters.

application area

Mainly used as a continuous conveying equipment for powder, small particle, and small block materials.

Fine chemical industry: pigments, dyes, coatings, carbon black, titanium powder, iron oxide, ceramic powder, heavy calcium, light calcium, bentonite, molecular sieve, kaolin, silicone powder, activated carbon, etc

Pesticide ores: urea, ammonium chloride, ammonium bicarbonate, soda powder, solid pesticides, tungsten powder, pesticide additives, copper concentrate powder, phosphate ore powder, alumina powder, etc

Building materials: cement, clay, yellow sand, quartz sand, clay powder, silica, limestone powder, dolomite powder, sawdust powder, fiberglass, silica, talc powder, etc

Food industry: flour, starch, grains, milk powder, food additives, etc.

Product features

A volumetric conveying device can achieve the transportation and metering of materials. Easy to achieve centralized control, improve automation level, and meet the environmental protection requirements of modern enterprises

2. Compact structure, small space occupation, and the ability to change the conveying direction in three dimensions.

The material being transported is in a sealed state from the inlet to the outlet flange. There is no need to install a dust collector at the exit. Gas can be filled during material transportation. Ensure no dust leakage into the environment during transportation.

The 4 materials are smoothly transported along the pipe without any internal movement, so there is less material damage. Slow curved transportation causes very few material particles to produce debris.

According to different feeding conditions, the distance between imports can exceed 10 meters.

The 6 sprockets have optimized shoulders, optimized design, and use hardened chains with minimal wear.

7 special conveying discs with extremely low friction coefficient and stable conveying capacity.