FO roughing classifier

Product Introduction

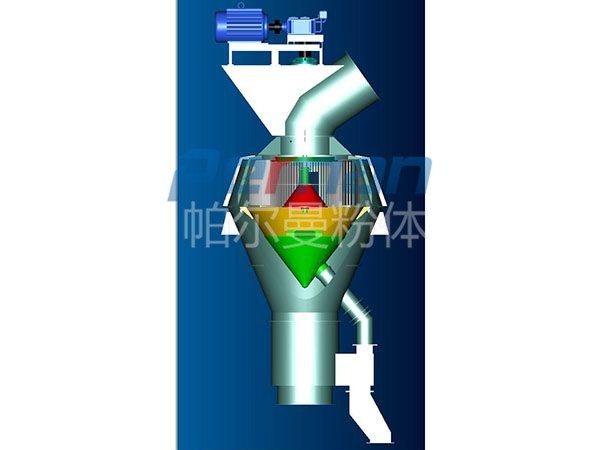

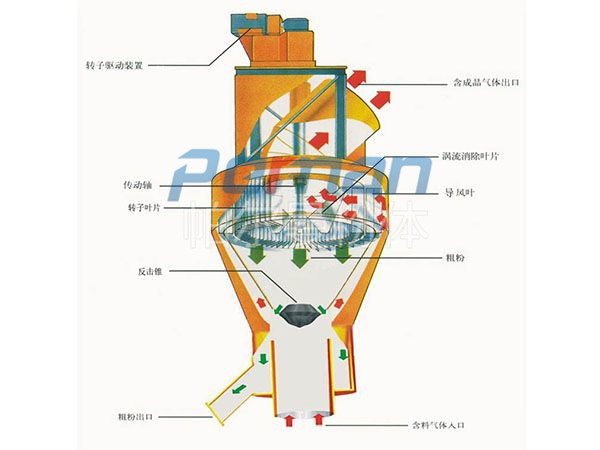

The airflow classifier, cyclone separator, dust collector, and induced draft fan form a classification system. Under the suction force of the fan, the material moves at high speed from the lower inlet of the classifier to the classification area with the rising airflow. Under the strong centrifugal force generated by the high-speed rotating classification turbine, the coarse and fine materials are separated. Fine particles that meet the particle size requirements enter the rotary fan separator or dust collector through the gap between the classification wheel blades for collection. Some of the coarse particles are carried by the fine particles and collide with the wall, and their velocity disappears. They descend along the cylinder wall to the secondary air outlet. Through the strong washing effect of the secondary air, the coarse and fine particles are separated, and the fine particles rise to the secondary classification area. The coarse particles are discharged at the discharge port.

● Suitable for fine classification of dry process micron level products, it can classify spherical, sheet-like, and needle shaped particles, as well as classify particles of different densities.

● The particle size of graded products can reach D97:8-150 microns, and the product particle size is stepless and adjustable, making it easy to change varieties.

● The classification efficiency (extraction rate) is 60% to 90%. Materials with good fluidity have higher classification efficiency, while those with poor fluidity have lower efficiency.

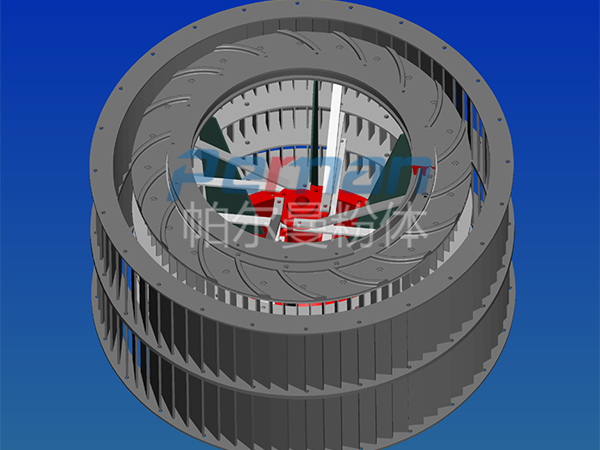

● Adopting a vertical graded turbine device, with low rotational speed, wear resistance, and low system power configuration.

● It can be used in series with multi-level classifiers to produce products with multiple particle sizes simultaneously.

● It can be used in series with ball mills, vibration mills, Raymond mills and other grinding equipment to form a closed loop.

● The control system adopts program control, with real-time display of operating status and easy operation.

● The system operates under negative pressure, and the dust emission does not exceed 40mg/m3. The equipment noise is reduced by noise reduction measures, and does not exceed 75dB (A).

● Divide the material into three layers, namely the coarse powder (d>150m) separation layer and the medium coarse powder (60m<d<150m); Separation layer, finished product fineness separation layer, layer by layer separation grinding, greatly improving mill output;

● Advanced classification principle: Combining multiple powder selection principles, the hierarchical configuration has high classification accuracy;

● The principle of mechanical vibration reduction is adopted, and the resonance frequency of the foundation is far higher than the natural frequency of the foundation to eliminate the influence of resonance on the use site. The classifier adopts stepless speed regulation, and the fine adjustment is convenient and sensitive.

● Large processing capacity, low energy consumption, graded product particle size range from 200 to 400 mesh

● Applicable fields: fly ash, steel slag, slag, bauxite, quartz, magnesium oxide, kaolin, ultrafine cement, etc.