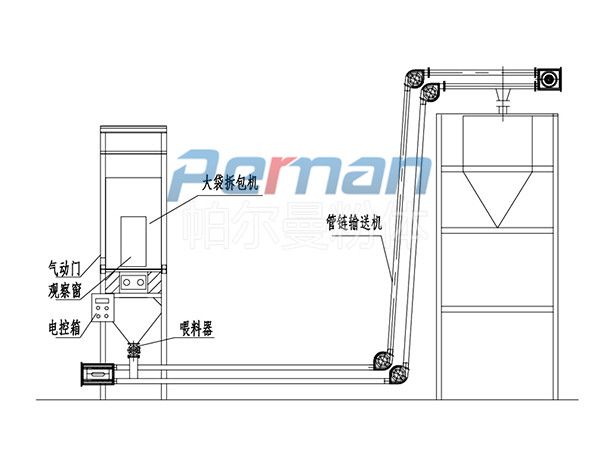

Unpacking pipe chain conveyor system

Product introduction

The unpacking pipe chain conveyor system is a multi-functional equipment system that cooperates with the dust-free unpacking machine and the pipe chain conveyor in production. It can realize automatic dust-free unpacking of materials in production and carry out subsequent material transportation. Improved production efficiency.

The production raw materials will enter the dust-free unpacking machine through belt conveyor for unpacking operation, and the separated bulk materials will directly enter the inlet of the pipe chain conveyor equipment for transmission operation at the discharge port.

The two ends of the conveying pipe are connected to the branch pipes provided at both ends of the driving box (driven box). The conveying chain passes through the inner hole of the feeding pipe and the branch pipe and is connected to the driving sprocket.

Features

1. The conveyor equipment adopts refined design and production, with longer service life and low daily maintenance frequency.

2. The internal friction coefficient is specifically designed to effectively reduce the wear caused by friction. Friction reduction is very effective in reducing noise generation.

3. Material transportation using chain plates can effectively reduce the accumulation of materials inside the pipeline and avoid material residues.

4. The conveyor runs smoothly, and the granular materials are protected to a large extent during the transmission process without causing any damage.

5. The material used in the production of the pipe chain conveyor is corrosion-resistant stainless steel, which can well protect the equipment itself and avoid damage to the equipment due to the corrosiveness of the material.

6. The ton bag opening machine has a simple structure and is easy to operate;

7. The beating equipment can ensure that the materials can smoothly enter the next step from the big bag;

8. The crusher breaks the agglomerates during the bag opening process to ensure the smooth progress of the next process;

9. Fully automated operation to improve production efficiency and reduce labor intensity;

10. Sealed bag opening prevents dust from flying and generates no heat, improving the working environment and reducing production costs;

11. Integrated design of bag opening, beating and crushing, compact structure and easy operation;

12. It can provide two forms of pneumatic or electric (hoist) control to achieve remote monitoring;

13. It can be equipped with pipe chain conveyor, screw conveyor, belt conveyor and other conveying equipment.

Product advantages

1. Dust-proof operation. Because the material is transported in a sealed pipeline environment, it is very effective in isolating the influence of dust in the environment and ensuring the purity of the material.

2. More energy-saving operation. In terms of power selection, we use a low conveying power of 1KW. In addition, the overall pipe chain conveying equipment has lower power consumption, but the conveying capacity has been very effectively improved. Under the same material transportation conditions, this kind of curved pipe chain conveyor can effectively reduce the energy consumption in transportation by about 50%-80% compared with the same type of air conveyor, thus better reducing production costs.

3. The design is more compact. The appearance of the pipe chain conveyor equipment is lighter in design, and the traditional design is abandoned in terms of knots, which saves space and makes it more compact.